Good clean fun times two

DLR is working at two new institutes in Cottbus to help make industry and flying more sustainable

Lowering CO₂ emissions is a pressing problem of our time. In Cottbus, people are working on solutions for it. Supported by funding for structural economic change, the German Aerospace Center (DLR) founded two institutes there that aim at making industry and aviation more sustainable through the use of new technologies.

Almost a quarter of all greenhouse gas emissions in Germany are attributable to the industry. The DLR Institute of Low Carbon Industrial Processes is out to change this and is setting its sights on a variety of sectors. “To shape the energy transition and reach our climate goals, we are focusing on a sustainable energy supply and the electrification of process heat, on the one hand, and new processes and increased efficiency in the industrial sector, on the other,” says Uwe Riedel. The professor of decarbonised industrial processes leads the institute.

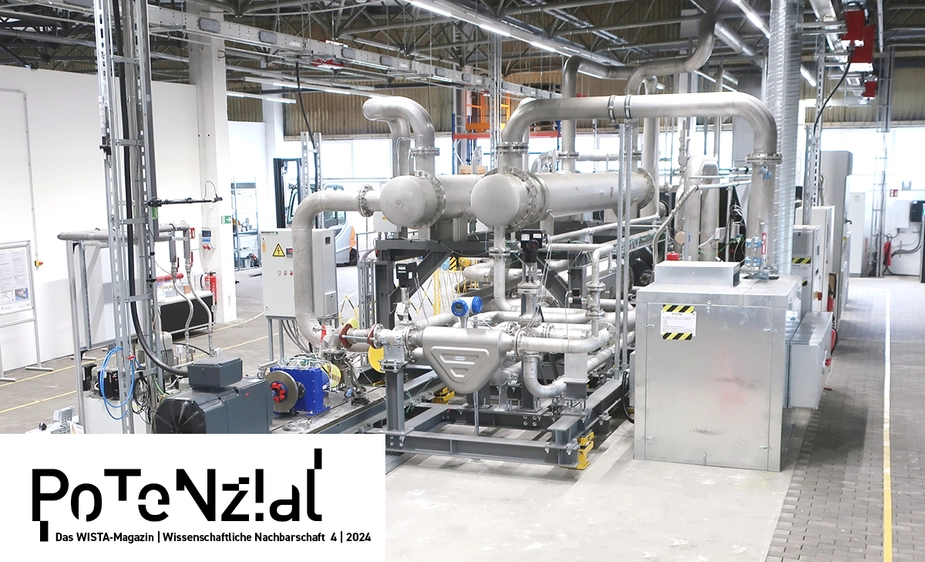

Founded in 2019, one of its key research areas is high-temperature heat pumps. Powered by renewable energy, they produce “green” heat for industrial processes. The special thing about them is that, unlike heat pumps used for heating buildings, these facilities work at temperatures up to 300 degrees Celsius. They can also take care of process cooling, which is essential for cooling-intensive industries like the food industry.

A further research focus of the institute is on low-carbon reducing agents. “Let’s take the steel industry for example,” explains Riedel. “They burn coal to extract oxygen from the iron ore. This creates large amounts of CO₂. We are now studying a climate-friendly alternative, the use of hydrogen. Instead of CO₂, which harms the climate, this results in only water.” Another department focuses on finding out whether such new technologies are also efficient, in addition to being good for the climate. “We develop models and use artificial intelligence to optimise industrial processes,” says Riedel. “Additionally, we delve into the question of economic viability.”

“Statistics say that civil aviation is currently accounting for three percent of the entire CO₂ emissions worldwide,” says Lars Enghardt, director of the DLR Institute of Electrified Aero Engines. “All the while, the global air traffic is continuously growing. The number of passengers transport is doubling roughly every 20 years.” For Enghardt, it is clear that this is a major challenge. The approaches he wants to utilise to push back range from climate-neutral, synthetic aviation fuel, to more electric conventional aircraft components, to fully electric alternative propulsion systems that are based on batteries or hydrogen. “We have set out that aviation must become more climate-friendly, preferably even climate-neutral,” he says. “Naturally, we are doing this in close collaboration with industrial partners who can produce marketable products from our ideas.”

For its research, DLR has purchased a 13,500-square-metre plot on the site of the former military airport in Cottbus and is currently equipping it with extensive testing technology. This is done in close coordination with the Center for Hybrid Electric Systems Cottbus (Chesco), a research factory spin-off from the Brandenburg University of Technology (BTU) Cottbus-Senftenberg that plans and builds its own test benches. “Together, we aim at making a testing landscape available that, as a whole, will be unique in Europe,” says Enghardt. “It can then be used by our industrial partners to put their aircraft engines to the acid test.” With a structural change moving from open-cast lignite mining to various high technologies, he sees the DLR institutes as opportunity makers for the region. “We want to create something new that enables us to partner up with local industrial companies,” he says. “And we want to offer a fresh perspective for small and medium-sized companies in the region, who will be able to reap the fruits of our research work.”

Kai Dürfeld for POTENZIAL

- Institute of Electrified Aero Engines (dlr.de/en)

- Institute of Low Carbon Industrial Processes (dlr.de/en)