New procedure for better thermoplastics

Research team at BESSY II was able to increase the performance of environmentally friendly materials

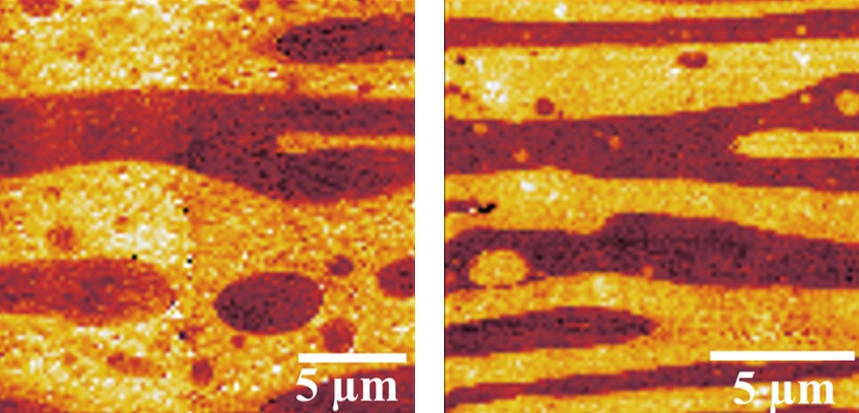

Bio-based thermoplastics are produced from renewable organic materials and can be recycled after use. Their resilience can be improved by blending bio-based thermoplastics with other thermoplastics. However, the interface between the materials in these blends sometimes requires enhancement to achieve optimal properties. A team from the Eindhoven University of Technology in the Netherlands has now investigated at BESSY II how a new process enables thermoplastic blends with a high interfacial strength to be made from two base materials: Images taken at the new nano station of the IRIS beamline showed that nanocrystalline layers form during the process, which increase material performance.

Bio-based thermoplastics are considered environmentally friendly, as they are sourced from non-petroleum-based raw materials and can be recycled just like standard thermoplastics. A thermoplastic base material is Polylactic acid (PLA), which can be produced from sugar cane or corn. Researchers around the world are working to optimise the properties of PLA-based plastics, for example by mixing them with other thermoplastic base materials. However, this is a real challenge.

A new process for better blends

Now, a team from the TU Eindhoven led by Prof. Ruth Cardinaels is showing how PLA can be successfully mixed with another thermoplastic. They developed a process in which certain PLA-based copolymers (e.g. SAD) are formed during production, which facilitate the mixing of the two raw materials by forming particularly stable (stereo)-crystalline layers at the interfaces between the different polymer phases (ICIC strategy).

Insights at the IRIS-Beamline

At BESSY II, they have now discovered which processes ensure that the mechanical properties of the mixed thermoplastic are significantly better. To do so, they examined pure 50% blends of the thermoplastics PLA and polyvinylidene fluoride (PVDF) as well as samples with the PLA-based copolymers at the IRIS beamline of BESSY II.

Stereocomplex crystals at the interfaces

Using infrared spectroscopy on the IRIS beamline, PhD student Hamid Ahmadi was able to demonstrate the formation of the PLA-based copolymer SAD. Further X-ray measurements showed how the formation of SAD affects the crystallisation behaviour. The new nano imaging and spectroscopy capabilities at the IRIS beamline allow for advanced chemical visualization and identification from sample areas as small as 30 nm. This precision was crucial in determining that the stereocomplex crystals are exclusively located at the interface. Infrared nanoscopy images showed a 200-300 nm thick layer of stereocomplex crystals at the interfaces.

Reason for more stability

The formation of stereocomplex crystals at the interfaces increases the stability and crystallisation temperature. Nucleation at the interface accelerates the overall crystallisation process within the PLLA/PVDF blend. In addition, the interfacial crystalline layer improves the transfer of mechanical stresses between the phases and thus the tensile properties; the elongation at break even increases by up to 250%.

“By elucidating the location and distribution of the crystalline layer in our samples, we could understand the procedure of mixing much better”, Hamid Ahmadi says. “By developing a new strategy we have cleared a path for the development of high-performance polymer blends”, Ruth Cardinaels adds.

Note: The IRIS beamline at BESSY II was extended by a nanomicroscopy facility in 2024, which makes it possible to create images of sample areas of ~30 nm and to carry out IR spectroscopy.

Publication:

Toughening immiscible polymer blends: the role of interface-crystallization-induced compatibilization explored through nanoscale visualization

Hamid Ahmadi, Paul M. H. van Heugten, Alexander Veber, Ljiljana Puskar, Patrick D. Anderson, Ruth Cardinaels

ACS Applied Materials & Interfaces (2024). DOI: 10.1021/acsami.4c10829

Contact:

Prof. Dr. Ir. Ruth Cardinaels

TU Eindhoven

Department of Mechanical Engineering

R.M.Cardinaels(at)tue.nl

Helmholtz-Zentrum Berlin für Materialien und Energie

IRIS THz/Infrared Dipole Beamline

Dr. Ljiljana Puskar

+49 30 8062-14739

ljiljana.puskar(at)helmholtz-berlin.de

Dr. Alexander Veber

+49 30 8062-13443

alexander.veber(at)helmholtz-berlin.de

Dr. Antonia Rötger

Press Officer

+49 30 8062-43733

antonia.roetger(at)helmholtz-berlin.de

Press release HZB vom 4.11.2024