Successful tests on underground heat storage in Berlin-Adlershof

Preliminary investigations by the GFZ Helmholtz Centre for Geosciences for Berlin's largest heat storage facility have been completed

Energy storage is an essential component of a secure, resilient and renewable energy supply. In order to balance supply and demand in the field of renewable heat supply, large heat storage facilities are needed, for example in the form of underground water reserves. One such aquifer heat storage facility is to be built in Berlin-Adlershof. Researchers from the GFZ Helmholtz Centre for Geosciences, led by Stefan Kranz and Lioba Virchow, have now carried out an extensive test programme there to evaluate the suitability of an aquifer at a depth of 350 to 400 metres for seasonal heat storage. As part of the hot push-pull test programme, several heat storage cycles were simulated over a short period of time to mimic later operation during seasonal storage.

Among other things, the behaviour of the water in the underground, chemical and microbiological properties, pressure and temperature around the borehole and other parameters were observed. The tests began in July 2025 and were successfully completed at the beginning of November. The main boreholes for the heat storage facility are planned by our industrial partner, BTB (Berliner Blockheizkraftwerks-Träger- und Betreibergesellschaft), in the coming months. The research borehole will then be used as a monitoring borehole for the heat storage facility.

Aquifer thermal energy storage for seasonal heat storage: the principle

In the permeable, groundwater-bearing rock layers located beneath Berlin and much of northern Germany, heat can be stored in the form of hot water. An Aquifer Thermal Energy Storage (ATES) system requires two deep wells: a hot well and a cold well. During the summer months, water is extracted from the cold well and heated, for example using renewable energy sources. The hot water is then injected into the hot well, where it is stored. During winter, heat is extracted from the hot well and used to heat buildings via a district heating grid. Once the heat has been used, the now colder water is pumped back into the cold well.

Underground aquifer heat storage facility in Berlin-Adlershof

At the site in Berlin Adlershof, the “Berliner Blockheizkraftwerks-Träger- und Betreibergesellschaft” (BTB) is constructing Berlin's largest heat storage facility as part of the “Reallabor GeoSpeicherBerlin” project – in cooperation with the GFZ Helmholtz Centre for Geosciences and TU Dresden. The envisaged storage aquifers are located at a depth of around 350–400 metres, where the temperature is around 23 °C. In summer, water at 95 degrees Celsius will be injected here. This will store excess heat from a wood-fired power station that uses waste wood to generate energy. In winter, the hot water is pumped back up and fed into the existing district heating network. Modelling shows that around 85 per cent of the heat can be recovered. The aim is to store over 30 GWh of renewable heat to contribute to the decarbonisation of district heating in south-east Berlin.

Simulation of cyclic storage using Hot-Push-Pull-Tests

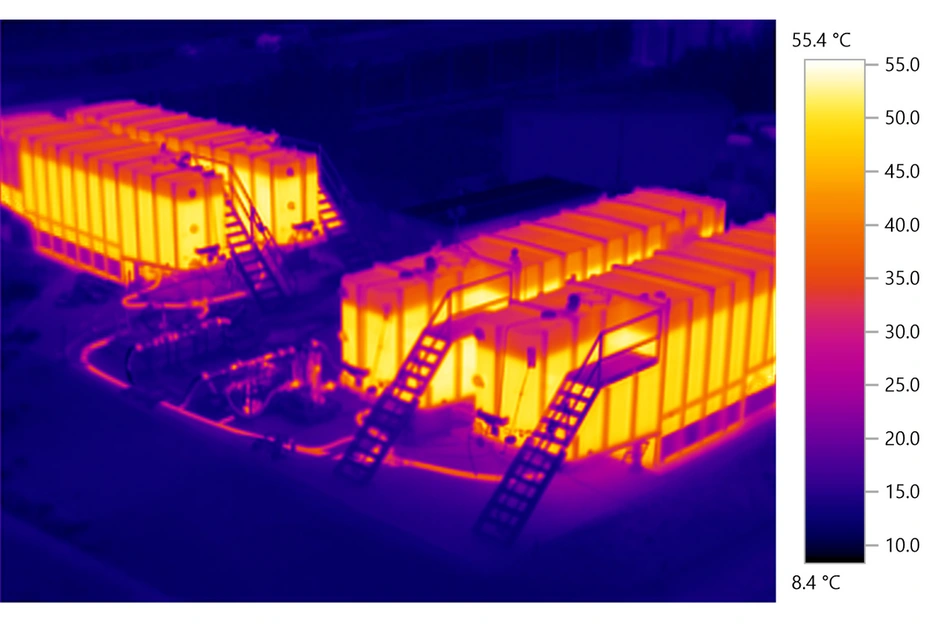

High-temperature ATES shows promise in enabling the storage of huge amounts of energy. However, the induced temperature change can affect the thermohydraulic storage behaviour, aquifer chemistry, microbiology and fluid-rock interactions in various ways. To investigate and understand these effects, and identify potential interactions, researchers from GFZ Section 4.3 “Geoenergy” have developed single-borehole tests that can be carried out on ATES research or pilot wells. In several push-pull phases, cyclic heat storage is simulated over a period of a few weeks. The tests began with the production of 260 m³ of formation water from GFZ's research well at the Berlin Adlershof site. The water was stored in four closed tanks filled with nitrogen to prevent chemical reactions that would occur if the water came into contact with oxygen in the air. Samples were taken for chemical and microbiological characterisation of the water to determine its undisturbed properties.

The Push-Pull Tests in detail

During the first push-pull cycle, 240 m³ of formation fluid was injected into the borehole without being heated. It was spiked with an inert chemical substance, or tracer, to be able to track it. After sixteen hours, the same volume was back-produced, and the amount of tracer produced was continuously monitored. This provides information about the storage formation's hydraulic properties.

In the following five cycles, the water was heated to 95 °C prior to injection and the tracer was added again. After 12–56 hours, the hot water was produced again to distinguish between kinetically fast and intermediate reactions.

Continuous monitoring of the physical and chemical properties, temperature, and pressure in the borehole and at the wellhead, as well as pH, specific electrical conductivity, redox potential, dissolved oxygen, density, and turbidity at the surface, was complemented by chemical and microbiological sampling.

Measurements of dissolved gases in the fluid were facilitated by Section 3.1 “Inorganic and Isotope Geochemistry”. Distributed Temperature Sensing and Distributed Acoustic Sensing using fibre optic cables installed along the well allow for monitoring of temperature along the hole well and monitoring of fluid movements at the filter screen, respectively, supported by researchers from Section 2.2 “Geophysical Imaging”.

After the fifth hot injection (push), the hot fluid was then left in the aquifer for 35 days and back-produced for the last time at the start of November. The intention behind leaving the hot water in the aquifer for such a long time was to observe any changes in the microbiological communities when they are in contact with increased temperatures for an extended period.

Resume: First promising results

Stefan Kranz, head of the “Geothermal Process Engineering and System Integration” working group in the GFZ Geoenergy section, summarises: ”The successful production and injection of water in and from the aquifer bodes well for the future operation of the ATES system. The hot push-pull tests have confirmed the good hydraulic properties of the Hettangian sandstones, which is reassuring for their suitability for heat storage. We clearly observed a temperature increase in the storage formation over the five hot push-pull cycles, reaching our target temperature of 95 °C during the final injection.”

Lioba Virchow, researcher in the working group “Geothermal fluids” of Section 4.3 “Geoenergy” emphasises: “The unique test setup has provided us with a multitude of data that allow for the in-depth characterisation of reservoir fluid and the chemical and microbiological processes during heat storage. Preliminary fluid-chemical results obtained during the tests show no evidence, at this stage, of processes that would contradict heat storage at 95 °C. The analysis of fluid samples and the evaluation of the data in the coming weeks and month will hopefully confirm these promising results and provide a solid scientific basis to evaluate environmental impacts of high-temperature aquifer thermal storage.”

Extensive undertaking with diverse, bundled expertise from the GFZ

The tests provide a unique dataset of great scientific value, as they scale up investigations from the laboratory to the field. This huge undertaking could only be achieved with broad support from several GFZ sections: for example from sections 4.4 “Hydrology”, from the Central Workshop, the Technical Services, and the Procurement Department, as well as from further scientists and technical staff from Sections 4.3 “Geoenergy”, 2.2 “Geophysical Imaging”, 3.2 “Organic and Earth Surface Geochemistry” and 3.1 “Inorganic and Isotope Geochemistry”.

A particular challenge was the power blackout in south-east Berlin in September that interrupted the test execution.

Contact:

GFZ Helmholtz-Zentrum für Geoforschung

Telegrafenberg, 14473 Potsdam

presse(at)gfz-potsdam.de

www.gfz.de

GFZ press release, 14 November 2025